Monterey Car Week is renowned for its extravagant gathering of the world’s most impressive vehicles, during which The Quail, A Motorsports Gathering, one of the most prestigious auto events in the area takes place.

At this year’s sold-out event, the father-son team behind Czinger Vehicles captivated the attention and admiration of auto aficionados with the global debut of their awe-inspiring and ultra-fast Czinger 21C Blackbird (which is a limited-production hypercar that is priced at appx. $2M).

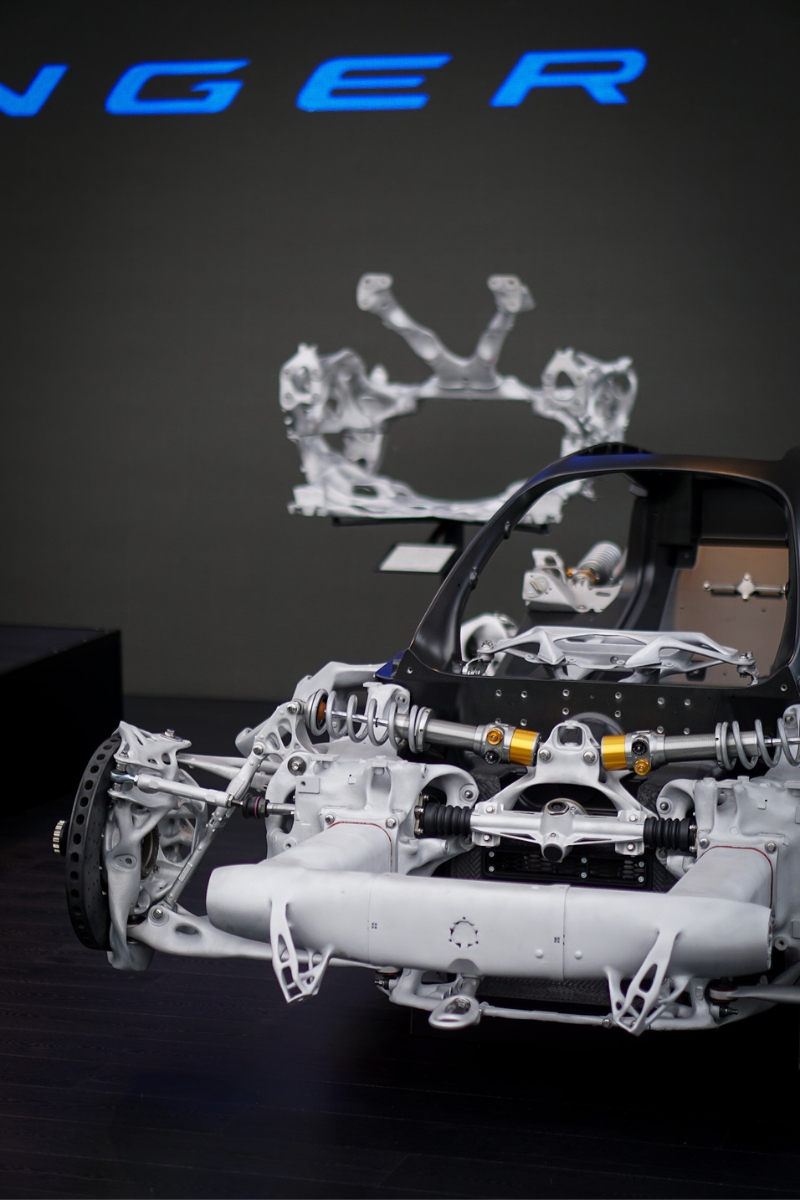

With a backdrop of the picturesque Quail Lodge & Golf Club in Carmel, California (where The Quail is hosted annually), the dynamic duo unveiled the world’s first human-AI designed, 3D-printed hypercar that was nothing short of a technological marvel (one that even Iron Man himself would be impressed by).

The 2024 Czinger 21C Blackbird, with its otherworldly design and astonishing performance, left car enthusiasts and experts alike in sheer amazement. But what makes this hypercar truly exceptional is not just its engineering brilliance but how it was designed and produced, thanks to the ingenious Co-Founders of Czinger Vehicles – Kevin Czinger, and his son, Lukas Czinger (both pictured below).

To start with – it’s not every day you come that I come across a father-son team with such an extraordinary impact on the rapidly evolving automotive industry, and not just for the development of this uber-cool hypercar.

As a powerhouse team, Kevin is a seasoned veteran with over 100 patents to his name and Lukas is a prodigious Yale engineering graduate. With their backgrounds and extensive knowledge, they are a testament to the power of generational collaboration. But this isn’t just a typical family business; if anything, theirs is a story that clearly exemplifies the point that innovation knows no bounds when fueled by the passion and ingenuity of two forward-thinking minds. In an article by YaleNews, Kevin was quoted saying that the 21C will be the “fastest street-legal car when it’s delivered later this year.” Pretty impressive, to say the least.

Within a few minutes of meeting the duo, after hearing Lukas speak about the technical components that were required to build this hypercar, I jokingly remarked to them that I should be Googling half of what he was saying. To say that he sounds like a walking encyclopedia of engineering and software architecture is an understatement. But, after learning about his father’s career, I can see that the apple didn’t fall far from the tree.

Kevin serves as the CEO and Founder of Czinger Vehicles and has a background in engineering and the auto industry (as the former Co-Founder, CEO, and President of Coda Automotive – which was a manufacturer and distributor of all-electric, zero-emissions cars and battery transportation systems), as well as experience as an operating executive in the tech industry. He also has an unquenchable thirst for pushing the limits of what’s possible in the world of automobiles.

As a result, his vision for Czinger Vehicles was to create hypercars that would outperform and out-innovate the competition. With his son Lukas by his side, he’s quickly achieving that lofty vision.

Lukas, who’s listed on the honorable Forbes ’30 under 30′ list, is also a force to be reckoned with, as the Co-Founder and COO. At just 28 years old, he has already amassed over 40 patents, a remarkable feat by any measure. His youth belies the depth of knowledge that he brings to the company. Lukas has played an integral role in the development of the 21C Blackbird, and his contributions are undeniable.

In addition to running Czinger Vehicles, Kevin and Lukas also run Divergent, which, as their company’s LinkedIn page explains “aims to revolutionize the auto industry through 3D printing. [Their] patented production system incorporates Nodes – 3D printed metal connectors – with lightweight materials to create strong and efficient complex structures. Divergent 3D’s technology eliminates tooling and drives radical innovation, capital reduction, and sustainability in vehicle manufacturing.”

So, not only are they leading Czinger in the design and production of their own hypercars, but through Divergent, they’re also helping other automakers utilize the advanced capabilities of 3D tech to supercharge the auto industry.

In an in-depth interview with Kevin and Lukas, they revealed the inspiration behind this futuristic-looking design and explained how they overcame challenges in producing this super-swift hypercar, especially given the fact that the company was launched just a few years ago, during the pandemic. During our conversation, Lukas and Kevin emphasized the importance of their collaborative approach, in addition to harnessing the power of advanced technologies.

Here’s a glimpse into our conversation:

CLP: To start with, I’m curious to learn about how you used AI design and 3D printing in your process. Can you share how these technologies shaped the performance, aesthetics, and even the soul of your hypercar?

LC: Absolutely! When we started, we really started as a technology company, which meant – software first, then materials. The software we created was really driven by the desire to make lighter and more efficient structures. We see the structures today that are machine-cast-extruded, and we can tell there’s mass on these structures. They’re heavier than they need to be because of the way they’re designed and because of the way that they’re manufactured, so we decided to address both of those problems. But we started with design. On the design front, we have a generative design engine that’s AI-driven. Essentially what we start with is an input file, and that input file is just the load cases, the volume that the car can consume before it clashes with something else, the requirements such as temperature, stiffness, and targets. Then we run it through our automated workflow, which is a software we’ve built over the last seven years. It’s got a bunch of different microservice engines running in parallel. And when we have completed that process, we essentially have added and subtracted material over 100,000 times against those requirements. And we’ve fully converged and actually found the optimal cradle frontier for that design, which means that I couldn’t shave another gram off of that design, without compromising one of those requirements. So, we’re really the first company that is making perfectly efficient structures in the engineering world.

CLP (to Kevin): That’s incredible! You must be very proud of him. He’s obviously a genius. I mean, I feel like I need to start Googling half of what he’s talking about.

KC: What’s unique about the two of us, and I really always say this is our company’s secret weapon is, it’s father-son generational power, because, rather than the father handing down to the son the reins of a business, this is one where we have complimentary skills. We’re both inventors of 600 or so patents and inventions behind this technology. I have 137 where I’m the leader and inventor, and Lukas is at 44, maybe it’s more now, and he’s going to catch up to me soon, I’m certain.

CLP (to Lukas): And you have an engineering background too, is that correct?

LC: I studied electrical engineering at Yale. Kevin’s got almost an engineering degree, but a much better background in some ways.

CLP (to Kevin): I know you were in private equity and you’ve also been involved in startups as well as automotive, is that correct?

KC: Yeah, I studied science and engineering both at Yale and Arizona State, in addition to having a Yale law degree. But I’d say the last 20 years I’ve really focused on invention, design, and engineering. I’d say the superpower is really us being two different generations with really complimentary skill sets, with some of them overlapping. People who are founders, inventors, and leaders, must be able to work together in a way where there’s total trust, respect each other’s judgment, and talk together. At the end of the day, if something is going on in the business and you need help or advice, you know you can turn to someone who is going to be there for as long as it takes to solve whatever the problem is.

CLP: I completely relate. I’m actually an executive at my family’s manufacturing company, a 50-year-old business in the party supply industry. So, while my background is totally different, I can completely understand that. Actually, that leads to my next question about family legacy and entrepreneurship, because I think that’s a really interesting dynamic because, when most people hear that you’re working with family, they say they couldn’t do that. It’s often very difficult because you’re not only blending different generations and the way they were brought up, but you’re also now marrying the way people approach business, handle their workload, and even the boundaries you have to create when you go home.

So, when do you turn it off, and when do you turn it on? And how do you enable yourselves to continue to evolve and respect each other, like you mentioned, in a professional capacity? I ask this, because, oftentimes in family businesses, usually the senior leaders will be the ones that will kind of prevent younger generations from stepping into their power because they generally think they have the authority, experience, and know-how. But it really sounds like you guys respect each other as equals in that sense.

KC: We are equals, we are partners. Part of it obviously is – to do business like what we’re doing – we’ve literally created a company that’s almost all inventions, then productized. That is a huge challenge. I’m enormously blessed that we both have the requisite talents to do that, but also, because we’ve had a relationship, where from the start, I’ve really enjoyed it. When he was young, we’d be doing things together – like working on cars, working on math problems, or even thinking about things together, it was always enormously fun. At a certain point, I hadn’t expected him to join the business, but he decided on his own to do that. And I have to say that it’s the single greatest blessing I’ve had.

CLP: That is awesome because it’s not only fulfilling on a corporate level of what you’re able to do and how you can expand but also on a personal level. In family businesses and entrepreneurship, in general, there’s so much growth happening in that development where you are pushing boundaries, stepping out of your comfort zone, and challenging yourself and your team. You’re wearing a lot of hats in the beginning, for sure, and I think that’s really a testament to both of your characters and your ability to work together as a team, which is great.

CLP (to Lukas): Growing up in an environment of innovation and automotive passion, how did your early exposure to your Dad’s ventures influence your career choices and your decision to become a Co-Founder of Czinger Vehicles?

LC: Great question. I think, for one, unique situations are different. And I’d say that the relationship that my Dad and I have is different than most people have with their Dad. That’s just the truth and it’s part of the foundation, and it goes back to me being very young. The moments we shared growing up together, he was certainly a mentor to me. We related over sports, we competed together, and I think earlier than usual, there was a mutual respect that formed there for me very early on. We never planned on working together, but I’d always been interested and involved with what he was thinking about, and I guess the most significant one of those was an EV business that he had started in China. I actually worked on the assembly line to gain experience because I was interested in EVs and cars, and it was a good fit. But, after that, I went to Yale, studied electrical engineering, graduated, and started working in finance. So, I had a good path cut out for me doing biotech M&A. I took a day off really just to support my dad, who was giving the original pitch for what Divergent could be, but it was a one-person business at that point, and he was on stage, and I watched it, and safe to say – I was pretty inspired by the idea of it. So, I went back to my finance job and thought it was quite good, but this seemed like something that was a once-in-a-lifetime opportunity to me.

CLP (to Lukas): It sounds like it was your calling.

LC: Yeah. So I gave him a call and said, ‘What if I come over and work with you?’ He basically said, ‘Are you sure? That’s a big risk to take. There are hardly any people in this company, it’s not a fully-funded deal, and it’s very ambitious.’ And I said ‘Yeah, I’m sure.’ I think in hindsight, I bet on him and he bet on me.

CLP: I have a question about 3D printing, which is a game changer in automotive manufacturing. How is this technology enabling you to create and integrate aerodynamic components that might have been impossible through traditional methods? And what components are specifically produced using 3D tech?

LC: On our vehicles, and we also do aerospace components now, we’ve got a very wide scope of parts. We actually make everything from heat exchange structures, like cold plates for ground vehicles and systems in the military, to drone structures, like aircraft and aircraft systems, to submersible structures, as we actually make submarine structures as well. But if you look at our car, nearly 100% of the chassis is 3D printed and designed with that software. So, the front bumper system, front frame, rear frame, and the braking system itself. Essentially, if it’s a part of the car that takes a high stress or high load, we’re going to design it with our software and 3D print it, so it’s going to save mass and it’s going to be on an architecture which allows us to iterate, as opposed to extruding or casting or machining something. Part of our advantage is how quickly we can iterate and improve, and that’s how we’ve made a record-breaking car in just 3 years. We’ve iterated so much faster than other vehicle manufacturers could because as soon as we get new input, a new idea, feedback from the field or the track or the sky, we can update our design, print the new design, and get it on the vehicle.

CLP: Very exciting! The Quail event marks a pivotal moment for Czinger Vehicles. How has the crowd’s response to the Blackbird affected you today? What emotions do you hope to evoke in today’s attendees?

KC: I think a sense of amazement. The vehicles that we’re displaying feature design elements that were done in honor of the SR-71 Blackbird, which was designed in the early 60s but is still the world’s highest-flying, fastest aircraft ever built, if you’re an engineer or designer, you look at that and go – oh my gosh, that looks like a spaceship coming from some future time. We wanted to create the same kind of emotional response, which is when you build something where form really follows function, and that AI-generated design with a human-directed aspect that Lukas is talking about is pure form-follows-function. People look at it and go ‘Wow! That looks like engineers from another galaxy landed here, set up a factory, and built something.’.

CLP: Well, you definitely captured that and it was very exciting to see the way you displayed this too. It created that emotional charge, so it heightened it for all of us.

CLP: What motivational philosophies do you instill in your team to inspire them to reach for the stars, just as you have?

LC: I think there’s a family spirit that echoes and surrounds our full team, not just for Kevin and myself. There’s a level of talent that’s needed, a level of capability, and also a level of commitment. We hire for all three of those things. And commitment is just as important to us. We can recognize very quickly if someone’s talented, and hardworking, but isn’t fully committed to the mission. It requires identifying with something to actually have that feeling, so we look for people who identify with our mission statement, as those are the people who end up doing the best work. Those are the people who have added 400+ patents to what Kevin and I started, and those are the leaders in our company today as well. That is the passion that drives us.

CLP: Family businesses often have deep-rooted values in legacy. So while your company is still new, how do you ensure that Czinger Vehicles’ legacy becomes an enduring testament to innovation, quality, and the pursuit of excellence?

KC: I’d say that everybody in the company is clear on what the mission is – including the missions of Divergent Technologies and Czinger Vehicles, intertwined. We create a tools company that literally can put in the hands of a small engineering team, tools that allow them to create perfectly-optimized structures, and then without having to put up a dollar of capital, they can send that data to one of our factories, which we’re going to start distributing and have it printed and assembled. That’s massive democratization of innovation power and manufacturing power. The structures that we build use the absolute minimum amount of material and energy, which obviously is critical to the sustainability of the planet, and all of the materials are close-loop recycled.

As evidenced by their expansionary thinking, swift growth, and pioneering spirit, Czinger Vehicles is not just another auto manufacturer making its mark on the world of hypercars; rather, it’s a testament to the limitless potential of a family business that is driven to supercharge a new era of automotive excellence through technological prowess.

Over the next week, I’ll be sharing more empowering words of wisdom and insightful ideas from other incredible car designers and successful executives who are leading the auto industry.

Stay connected on MSN or subscribe to Inspirations & Celebrations for access to in-depth interviews and stories that will motivate, empower, and inspire you.